Operating a drill machine is essential for various tasks, whether you’re working on a professional construction site or tackling a DIY project at home. This versatile power tool provides users with practical, reliable, and efficient solutions to meet their drilling and fastening needs. By understanding how to use a drill machine safely and effectively, you can maximize its potential while ensuring your safety and maintaining the quality of your work. Drill machines simplify complex tasks and save time, making them an indispensable tool for both professionals and hobbyists.

This guide explores how to operate a drill machine effectively, focusing on safety precautions, step-by-step instructions, and tips for achieving the best results. Additionally, we’ll discuss key benefits, such as enhanced productivity, time savings, and improved ease of use, all of which contribute to simplifying daily tasks.

Understanding the Basics of a Drill Machine

Before using a drill machine, it’s crucial to understand its components and functions. Drill machines are power tools designed for creating holes or driving screws into materials such as wood, metal, or concrete. They come in various types, including corded, cordless, hammer drills, and rotary hammers, to suit different needs.

The basic parts of a drill machine include:

- Chuck: Holds the drill bit in place.

- Trigger: Activates the motor to rotate the drill bit.

- Speed Control Switch: Adjusts the speed of operation.

- Torque Setting: Controls the rotational force applied.

- Handle and Grip: Provides stability during use.

By familiarizing yourself with these components, you can ensure that you select the right settings and attachments for your specific task.

It’s also important to identify the correct drill bit type for your project. For instance, masonry bits are ideal for concrete, while twist bits work best for wood and metal. Selecting the right bit not only improves efficiency but also protects the integrity of the material you’re working on.

Preparing the Workspace and Tool for Safety

Safety is paramount when operating a drill machine. Proper preparation can significantly reduce the risk of accidents and enhance overall efficiency. Here are some essential steps to ensure a safe work environment:

- Organize Your Workspace: Keep the area tidy, removing any clutter or items that could hinder movement or cause tripping. Ensure adequate lighting to clearly see your workpiece.

- Wear Appropriate Protective Gear: Safety goggles protect your eyes from flying debris, while gloves offer a firm grip and protect your hands from minor injuries. Hearing protection may also be necessary when working with loud machinery.

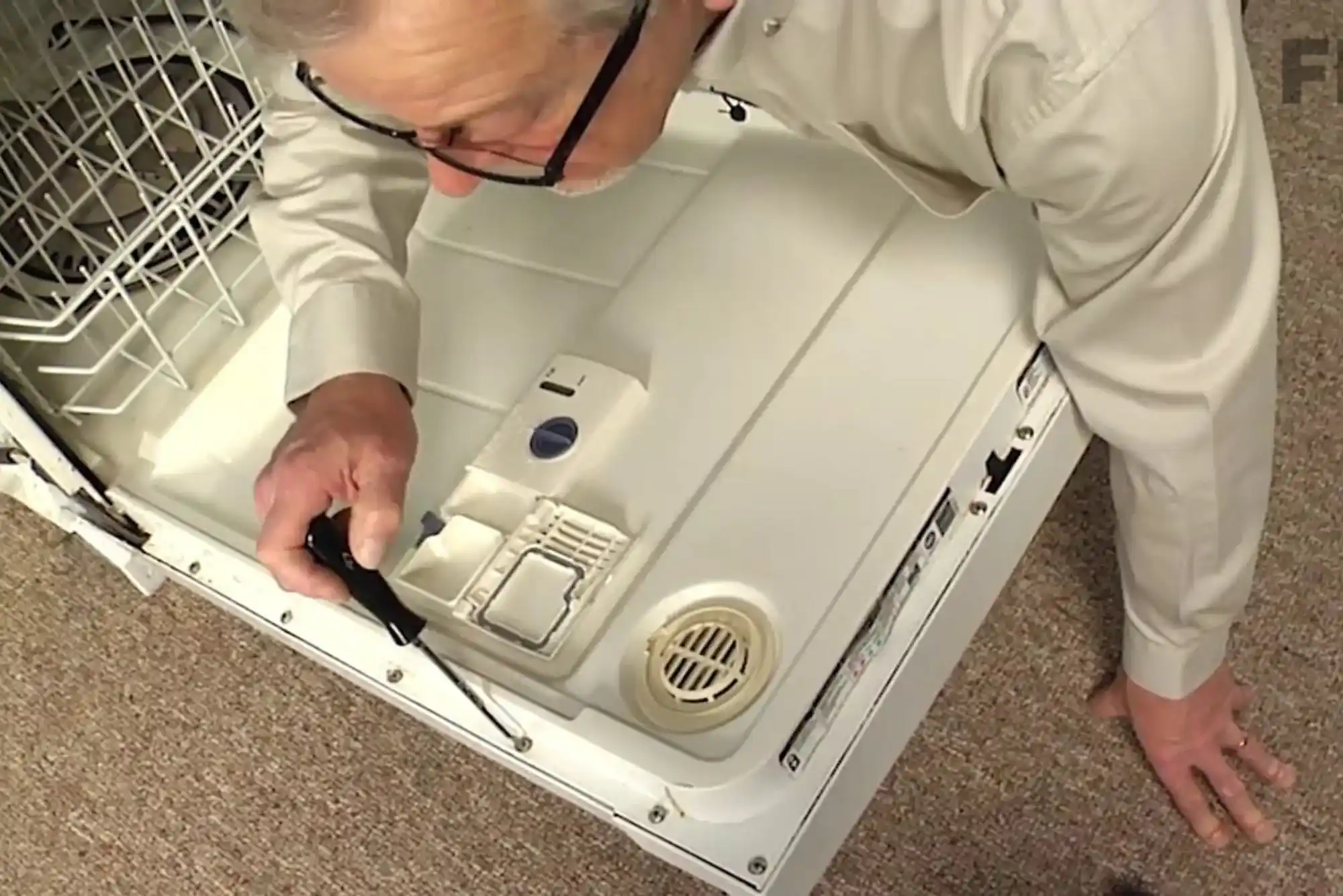

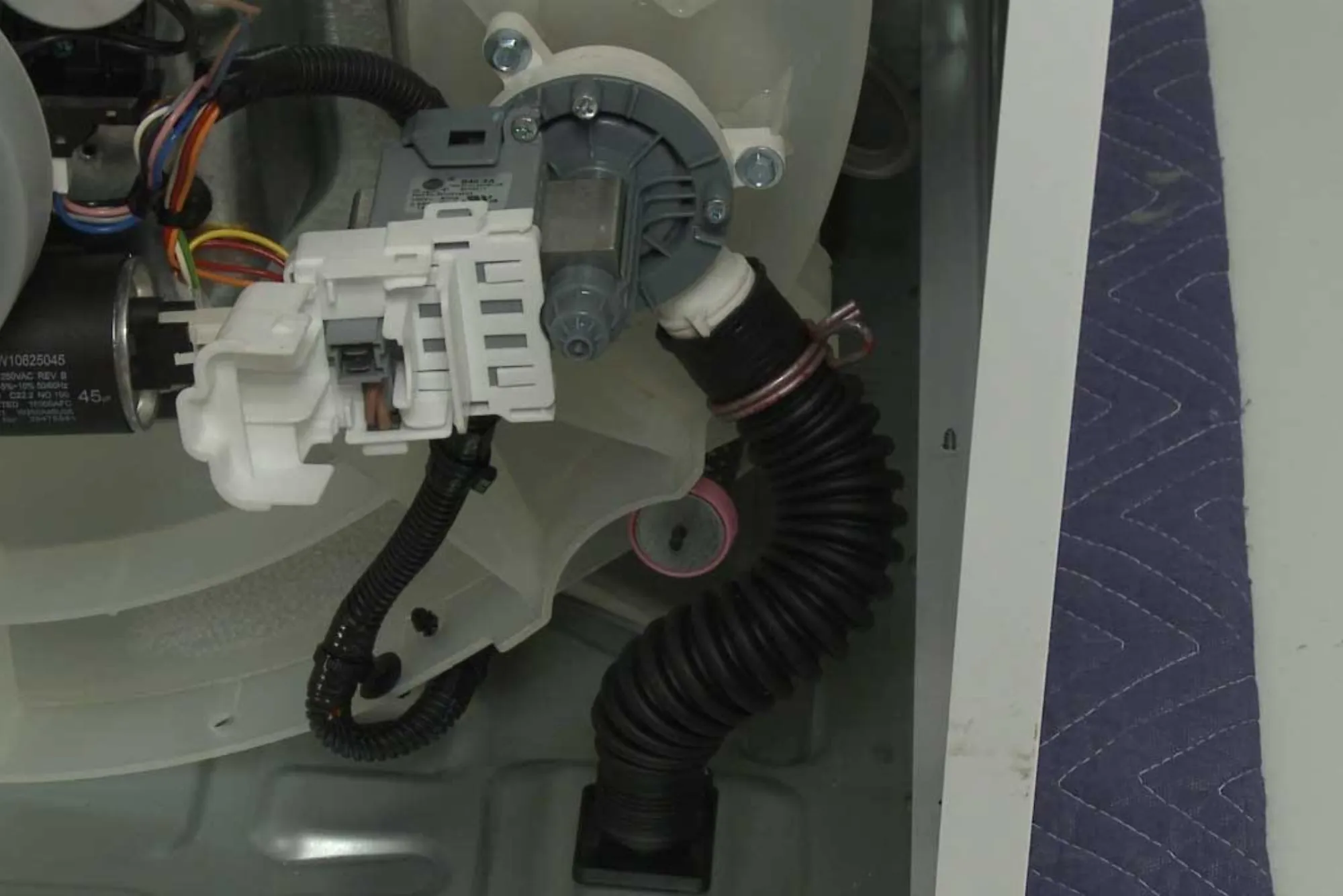

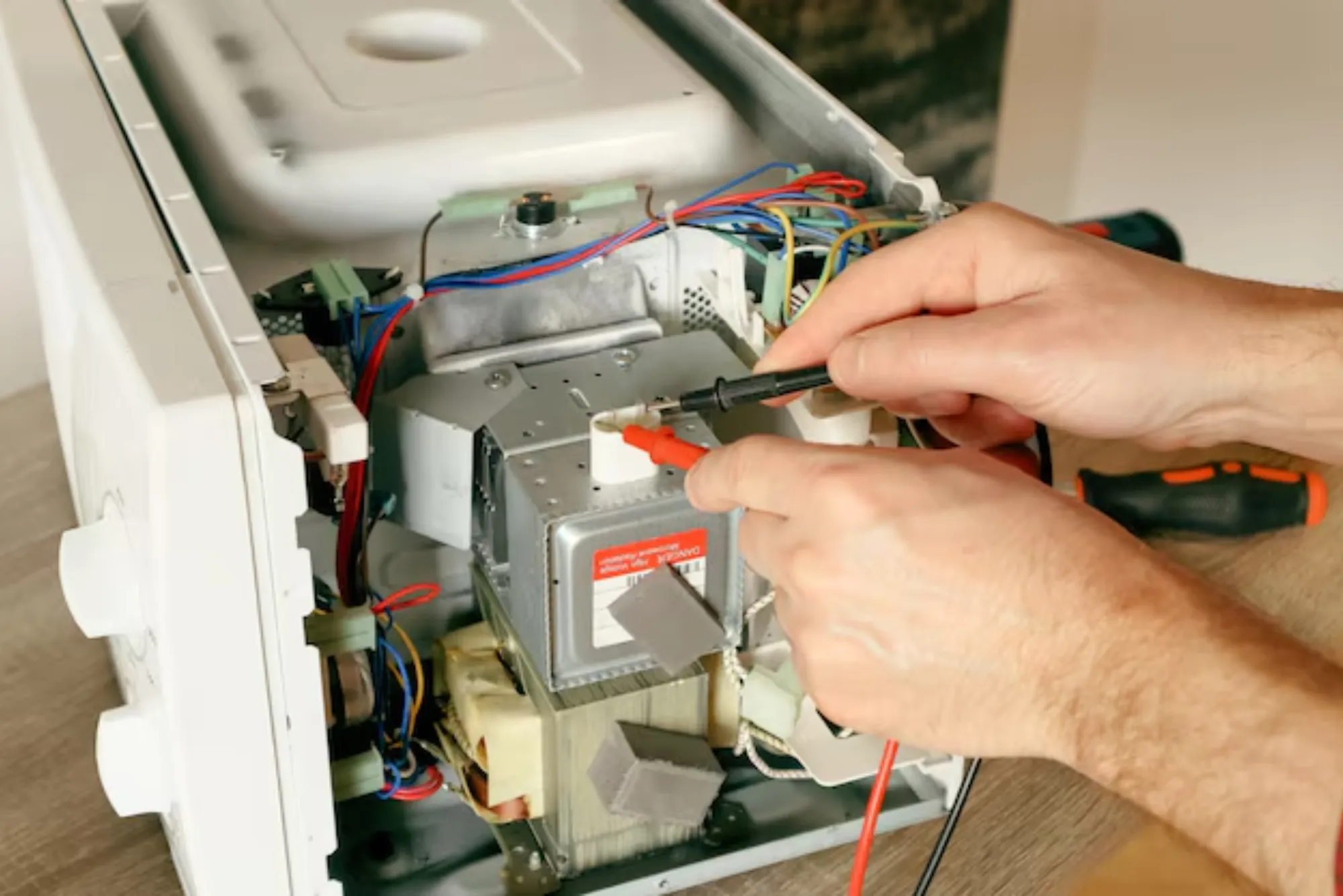

- Inspect the Drill Machine: Before starting, confirm that the drill machine is in good condition. Check for loose wires, worn-out components, or any signs of damage that could compromise its performance.

- Clamp the Workpiece: Secure your material with a clamp or vise to prevent it from shifting during operation. This provides better stability, ensuring precise and clean drilling results.

- Keep a Clear Exit Strategy: If you’re drilling through walls or ceilings, ensure clear pathways to avoid hitting electrical wires or pipes. Use a stud finder to locate potential obstructions.

By taking these precautions, you’ll set the stage for a smooth and accident-free drilling experience.

Step-by-Step Guide to Safely Operating a Drill Machine

Operating a drill machine requires a combination of skill, focus, and adherence to best practices. Below are step-by-step instructions for safely and effectively using the tool:

- Choose the Correct Drill Bit: Match the drill bit to your material and desired hole size. Secure the bit tightly in the chuck to avoid wobbling during use.

- Adjust the Speed Settings: High speeds are suitable for lightweight materials like wood, while slower speeds provide better control for harder materials like metal or concrete.

- Position the Drill Machine: Align the drill perpendicular to the surface to achieve accurate results. Hold the machine firmly with both hands for stability.

- Drill a Pilot Hole: For larger holes, start with a smaller pilot hole to guide the drilling process and reduce stress on the bit.

- Apply Steady Pressure: Gently press the drill against the material without forcing it. Too much pressure can cause the bit to break, while too little may result in uneven results.

- Control the Drill During Operation: Keep an eye on the speed and angle of the drill. If you notice overheating or excessive vibrations, pause briefly to reassess.

- Clean the Debris: After completing the hole, remove the drill bit and clean any debris. This ensures a neat finish and prevents material damage.

By following these steps, you can confidently handle any drilling project while ensuring consistent and high-quality outcomes.

Tips for Improving Efficiency While Using a Drill Machine

Maximizing your drill machine’s efficiency requires implementing strategies that expedite tasks without compromising safety or accuracy. Here are some practical tips:

- Use the Right Attachments: Invest in specialized attachments such as countersink bits, hole saws, or mixing paddles to expand the machine’s functionality and streamline complex jobs.

- Practice Proper Maintenance: Regularly clean your drill machine and lubricate moving parts to prolong its lifespan and maintain peak performance.

- Leverage Depth Guides: Use the machine’s built-in depth guide to avoid drilling too deeply into the material, preventing unnecessary damage and wasted effort.

- Take Breaks as Needed: Overextending the machine can cause overheating. Allow it to cool between uses to preserve its motor and components.

- Work Smart, Not Hard: Employ features like variable speed control or cordless mobility for greater flexibility and adaptability while handling different tasks.

Applying these tips can help you achieve greater productivity while conserving time and energy during your projects.

Common Challenges and Solutions for Drill Machine Users

Despite their versatility, drill machines can present certain challenges. Here’s how to troubleshoot common issues:

- Slipping Drill Bits: If the bit slips during use, ensure it’s correctly inserted into the chuck and tightened. Consider using a higher-quality bit for better grip.

- Overheating: Frequent overheating could indicate overuse or inadequate lubrication. Switch to high-quality lubricants and give the machine breaks between sessions.

- Uneven Holes: Misaligned holes may stem from incorrect positioning of the machine. Always double-check the angle and stabilize the machine before drilling.

By addressing these challenges proactively, you can maintain smooth and trouble-free operation.

Key Benefits of Using a Drill Machine Correctly

The proper use of a drill machine offers a plethora of advantages, such as:

- Enhanced Productivity: Drill machines save time on repetitive tasks while ensuring professional-grade results.

- Time Savings: Quick setup and efficient performance allow users to complete projects faster.

- Ease of Use: Modern features like ergonomic designs and lightweight frames enhance comfort, making them ideal for extended use.

- Versatility: Beyond drilling, these machines can mix paints, polish surfaces, and drive screws, simplifying multiple tasks.

Whether you’re a professional builder or a DIY hobbyist, these benefits significantly improve day-to-day efficiency and open up new possibilities for creative projects.

Looking for reliable power tools in the UAE? Check out WikiPoint.ae for a wide range of high-quality tools, from drills to saws, perfect for any project.

Final Thoughts on Safely Operating a Drill Machine

Mastering the safe and effective operation of a drill machine is vital for achieving optimal results while ensuring user safety. By selecting the right tools, adhering to safety protocols, and implementing best practices, you can harness the full potential of your drill machine. This essential tool simplifies intricate tasks, saves precious time, and adds precision to your projects.

For unmatched performance and reliability, consider exploring Drill Machine options tailored to your needs. Start your next project with confidence and experience the efficiency and convenience of this versatile power tool!